Thank you for you interest in our valves, follow is brief introduction of this prodcut,welcome to contact us for any other technical information or latest price.

1. Brief introduction of Cast Iron Bottom Valve

The bottom valve is mainly applied to mechanical equipment for slurry treatment, such as pumps. Usually, the bottom valve will be installed at the bottom of the pump suction pipe to prevent slurry backflow.

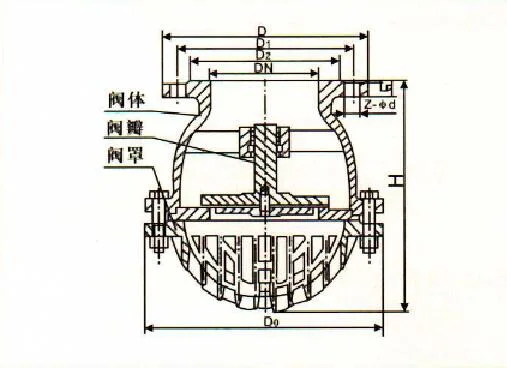

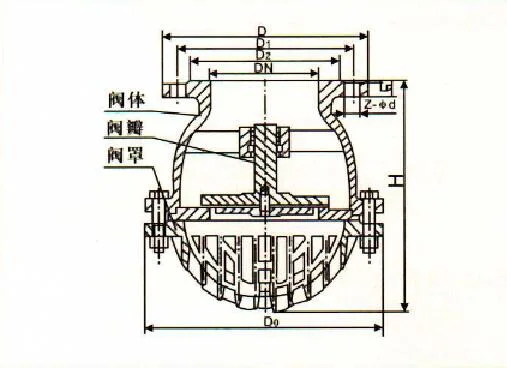

2. Structure of Cast Iron Bottom Valve:

At the end of the valve in the valve cover there is a plurality of water inlet, and is equipped with a screen, in order to reduce debris flows, reduce the blocking probability of the valve. Although the bottom valve is equipped with an anti clogging screen, the bottom valve is generally suitable for cleaning media, and the medium with high viscosity and particles is not suitable for using the bottom valve.

The bottom valve is a kind of energy saving valve. It is usually installed at the bottom end of the pump suction pipe, which limits the liquid in the pump pipe to return to the water source and plays a function of only entering. There are many intake and reinforcing bars on the valve cover, which are not easy to block up, and are mainly applied to the pipeline for pumping. The function of water channel and support is single, double and multi flanges, with flange connection and threaded connection. Other names: inner thread lift bottom valve - bottom hole valve, water absorption valve, water filter valve, lotus head; lift bottom valve - flange bottom valve; swing bottom valve - Flanged swing bottom valve.

At the end of valve welding in the bottom of the container, which can achieve the best emptying, cleaning, disinfection effect. In addition, the working medium can be well mixed according to the technological requirements during operation. Tank bottom valve as close to the bottom of the tank wall, so as to achieve the effect of no dead ends.

WENZHOU SOLID MECHANICAL EQUIPMENT CO., LTD

1. Brief introduction of Cast Iron Bottom Valve

Cast Iron Bottom Valve is actually a kind of check valve, which plays a role in preventing water from backflow.

At the end of the valve can be divided by material of plastic and metal valve, valve can be divided into the general valve and the bottom valve of washing water.The bottom valve is mainly applied to mechanical equipment for slurry treatment, such as pumps. Usually, the bottom valve will be installed at the bottom of the pump suction pipe to prevent slurry backflow.

2. Structure of Cast Iron Bottom Valve:

At the end of the valve in the valve cover there is a plurality of water inlet, and is equipped with a screen, in order to reduce debris flows, reduce the blocking probability of the valve. Although the bottom valve is equipped with an anti clogging screen, the bottom valve is generally suitable for cleaning media, and the medium with high viscosity and particles is not suitable for using the bottom valve.

The bottom valve is a kind of energy saving valve. It is usually installed at the bottom end of the pump suction pipe, which limits the liquid in the pump pipe to return to the water source and plays a function of only entering. There are many intake and reinforcing bars on the valve cover, which are not easy to block up, and are mainly applied to the pipeline for pumping. The function of water channel and support is single, double and multi flanges, with flange connection and threaded connection. Other names: inner thread lift bottom valve - bottom hole valve, water absorption valve, water filter valve, lotus head; lift bottom valve - flange bottom valve; swing bottom valve - Flanged swing bottom valve.

At the end of valve welding in the bottom of the container, which can achieve the best emptying, cleaning, disinfection effect. In addition, the working medium can be well mixed according to the technological requirements during operation. Tank bottom valve as close to the bottom of the tank wall, so as to achieve the effect of no dead ends.

| Model | DN(mm) | Dimension(mm) | Weight(kg) | |||||||

| D | D1 | D2 | b-f | Z-Φd | D0 | h0 | H | |||

| H42X-2.5 | 50 | 140 | 110 | 90 | 16-3 | 4-14 | 135 | 17 | 142 | 4 |

| 65 | 160 | 130 | 110 | 16-3 | 4-14 | 168 | 25 | 180 | 6.5 | |

| 80 | 185 | 150 | 125 | 18-3 | 4-18 | 198 | 32 | 197 | 8.5 | |

| 100 | 205 | 170 | 145 | 18-3 | 4-18 | 247 | 40 | 230 | 143.5 | |

| 125 | 235 | 2500 | 175 | 20-3 | 8-18 | 272 | 43 | 270 | 18 | |

| 150 | 260 | 225 | 200 | 20-3 | 8-18 | 315 | 38 | 297 | 24 | |

| 200 | 315 | 280 | 255 | 22-3 | 8-18 | 405 | 65 | 382 | 38 | |

| 250 | 370 | 335 | 310 | 24-3 | 12-18 | 465 | 84 | 460 | 64 | |

| 300 | 435 | 395 | 262 | 24-4 | 12-23 | 510 | 90 | 530 | 98 | |

3. About our Products:

WENZHOU SOLID MECHANICAL EQUIPMENT CO., LTD