Sign up to the CM newsletter for free, delivered direct to your inbox.

The UK’s Most-Read Construction Magazine. Stainless Steel Pipe

Construction Management is the highest circulation construction-based publication serving the UK built environment.

Klondyke Garden Centre in Polmont, Falkirk, reopened in 2021 after a major refurbishment. It included a large extension, additional retail space and a new 300-seat restaurant with separate coffee bar.

Wanting an environmentally friendly and reliable heating system, Klondyke was keen to avoid the use of chemical inhibitors for the heating system. Inhibitors are generally used to prevent rust and internal corrosion from occurring inside heating systems.

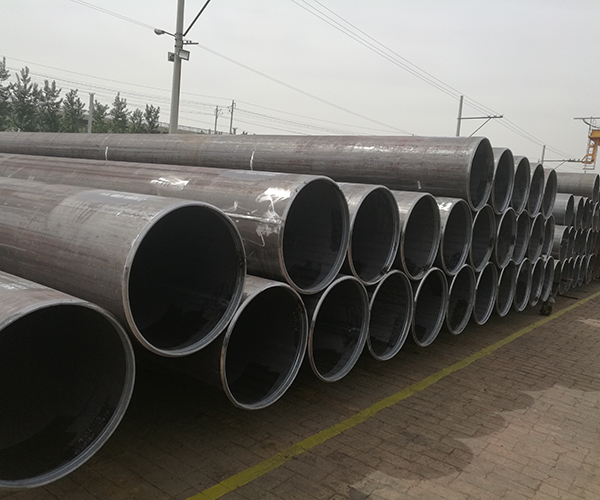

Instead, innovative monitoring technology has been combined with Geberit’s precision carbon steel pipes to achieve a long-lasting system which offers a high level of protection with early warning if problems should occur.

M&E contractor VWG Mechanical designed a system which is automatically vacuum degassed and pressurised, taking advantage of soft local water to minimise oxygen content and corrosion build up.

It also includes innovative Risycor electronic coupon method (ECM) monitoring of corrosion and pressure for ongoing protection. When maintained with minimal system water loss and vacuum degassed make up, it is expected to last for at least 25 years.

The system uses Geberit’s Mapress press fit system, with precision carbon steel pipes, SpiroPress Vacuum degassing and auto makeup, and the Risycor ECM monitor for enhanced corrosion protection. Durable, proven over many years and more cost-effective than stainless steel and copper (subject to copper prices), carbon steel offers a viable solution for closed water systems if monitored and protected properly.

In addition, Mapress is quicker to install than traditional jointing methods because it requires no hot works, no soldering and no threading. It is designed so that any connections not pressed during installation can be visibly detected during testing as it would purposefully leak.

The unique pressing indicator consists of a thin plastic foil encasing the pressing shoulder, which gives a visible indication of a pressed joint when the foil is removed during the pressing operation.

The system offers Klondyke an environmentally-friendly and reliable heating system, on which the manufacturer and contractor have worked together to overcome the corrosion challenge. Early monitoring from the project demonstrates the success of the installation.

Chris Dooling, managing director of VWG Mechanical, said: “We’re aware of recent negative press surrounding carbon steel yet we’ve never lost confidence in the material or doubted its reliability. We chose Geberit Mapress carbon steel along with Electronic Coupon Method (ECM) monitoring for this project because of the cost benefits, as well as the technical expertise and support provided by Geberit and HASL. It has enabled us to proactively respond to any maintenance requirements, ensuring smooth operation and longevity of the system.”

Gordon Pringle, from distributor HASL, added: “By adopting correct installation and mechanical procedures alongside cost-effective monitoring to alert those responsible when things go awry, they can respond quickly to provide proactive maintenance as and when required. Condition-based maintenance as it should be.”

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

NASC Yearbook 2022 is now available to read in digital format.

Pls1 Spral Pipe This is not a first step towards a paywall. We need readers to register with us to help sustain creation of quality editorial content on Construction Management. Registering also means you can manage your own CPDs, comments, newsletter sign-ups and privacy settings. Thank you.